If the Astro-Physics 1600GTO German Equatorial has all the features you desire, but is a bit larger than you need, the 1100GTO was developed just for you. This medium-sized mount travels eagerly to star parties where your 12V battery will keep it running all night or is content to stay at home in your observatory, ready to image while you sleep. The AP 1100GTO mount is built from the ground up to be a precision imaging platform while still remaining totally user-friendly. Consider these advantages and features:

Throughout the years, the Astro-Physics design team has sought to continually improve our product line, particulary as the technological demands for ever more precise equipment has increased.

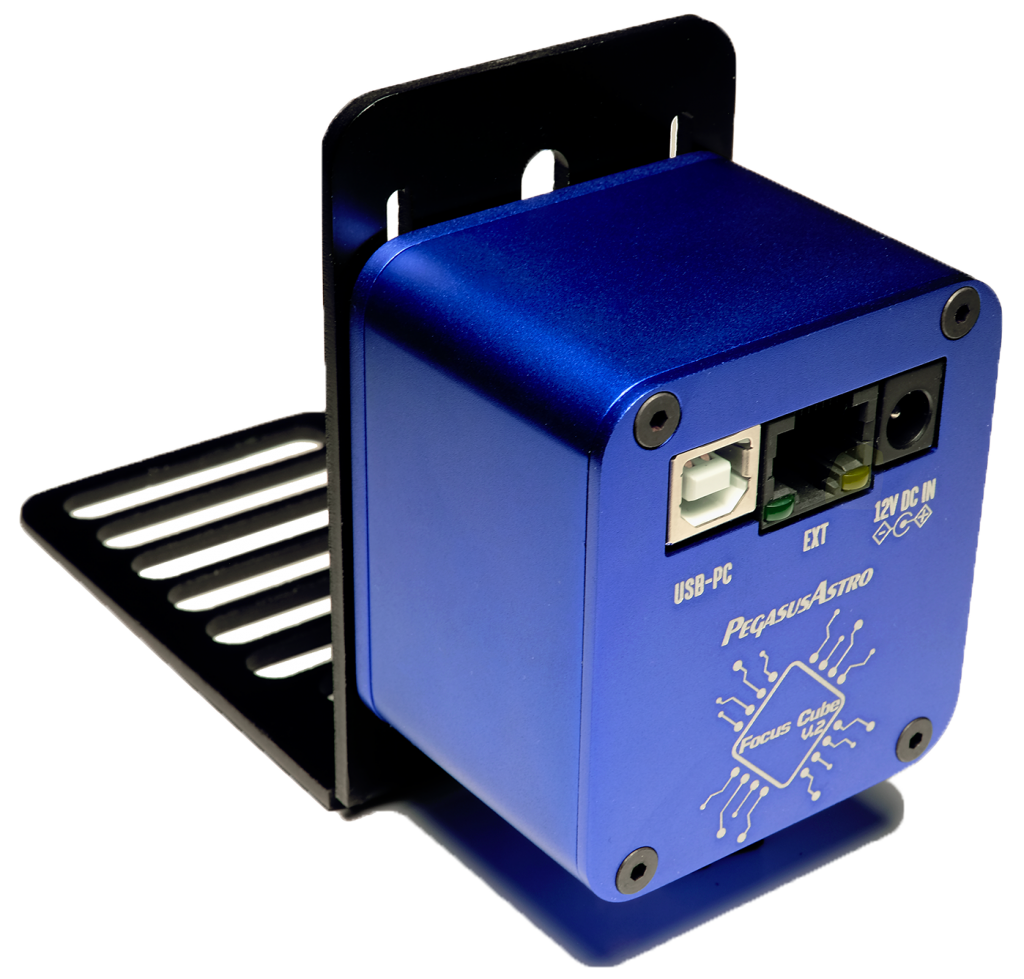

GTOCP4 Control Box

The GTOCP4 Control Box offers multiple connection options to suit your requirements including wifi, ethernet, USB and serial ports. In addition to all the features carried forward from previous control boxes, the GTOCP4 applies safety slew logic to all slew commands. Future firmware updates will available via direct downloads.

Auto-Adjusting Motor/Gearboxes

Our new motor/gearboxes were designed to be more responsive for precision astro-photography, while at the same time making it super easy to use and adjust. Here are some key features:

- For time frames or questions, please contact us at 800-483-6287.

- Spring-loaded worms maintain full contact under all guiding and slewing conditions

- Automatic setting for worm mesh requires no adjustments over long time periods

- Very easy to do precision balance by new mechanism which allows full backing off the worm from the worm wheel

- Very low backlash geartrain eliminates Dec reversal delays and provides high position accuracy during guiding

- Geartrain components are made with high-strength stainless alloy for extremely low wear even with continuous slewing applications

- Worms made with high-strength alloy eliminates wear during long periods of slewing, especially useful for remote setups that do survey work

- All worms are tested to meet stringent periodic error specs. Error is measured with PEMPro and the resultant compensating curve is loaded into the servo controller so you can use the PEM function to remove 90% of the variability even in non-encoder mounts.

Features of the 1100GTO (as compared to the 900)

- For time frames or questions, please contact us at 800-483-6287.

-

Dec. axis gear increased to 7.2" (183mm)for higher payloads and more stability.

-

Azimuth adjusters have been repositioned to the rear of mount which allows you to make minor corrections quite easily without reaching or moving around the mount. Since the knobs are now in front of you as you look through the polar scope, the graduations can be more easily seen as you dial in your position.

-

Built-in precision-rotating pier adapter is now included and not purchased as a separate item.

-

Major altitude adjustmentsare extremely quick and easy to make by simply shifting the position of the altitude adjustment bar into a new slot. The large "captain's wheel" knob, convenient to grasp and turn, performs the fine adjustments. If you travel to a star party at a different latitude, the changes to your setup are quickly made and allow you to transport the RA assembly in a more compact, zero degree latitude configuration.

-

Altitude range now extends from 0-78 degrees in its normal configuration. The Hi-Low Wedge is no longer necessary.

-

Right-Angle Polar Alignment Scope (optional) can be used without the need for an additional adapter.

-

Unobstructed Dec. opening for Polar Alignment Scope allows greater field of view for both the Astro-Physics Right-Angle or the Losmandy Style Polar Alignment Scopes.

-

Internal routing of motor cables to remove the possibility of snagging.

-

Easily route additional cablesthrough the large openings in the R.A. and Dec. axes. The top of the Dec. axis separates so that you can add cables with large connectors.

-

Right-angle connectors are used where applicable to reduce strain on the cables.

-

Improved clutch system with NO clutch plugs that can potentially deform over time if they are overtightened. This issue has been eliminated.

- Clutch can be set to any amount of engagement up to complete locking of the axes so nothing can slip.

-

Control box mounted vertically rather than on the top to reduce the possibility of moisture getting into the electronics in damp environments.

-

Precision bubble level built into mount base.

-

Stainless steel lanyard post on either side of base to hang your keypad.

-

Greater capacity to provide a rigid platform for fairly large instruments or side-by-side setups.

-

Absolute Encoder option to provide error-free tracking, software readable absolute position, customizable home and limit functions for robotic imaging. This option can be installed when you purchase your mount (order either the 1100GTO-AE or 1100GTO-AEL version) or you can purchase the option as an upgrade kit when you are ready to take advantage of its capabilities.

-

Limit/Homing Switch option to provide home and limit functions using a mechanical switch (does not use the absolute encoders). This option will be available in the future.

Astro-Physics 1100GTO = Versatility

Portable

Extremely solid, rugged, high payload mount, yet the equatorial head comes apart into two components for hassle-free field setup.

Operate with 12V battery

You can take it to the darkest skies and power it with a commonly available 12V battery. In the observatory, we suggest a minimum 5 amp filtered, regulated power supply like our 13.8-volt, 5-amp Power Supply (PS138V5A). For a heavy payload in cold conditions, we offer a 15-volt, 12-amp power supply (PS15V12AC).

Clutches

Allow manual operation if power is not available. Use the clutches to easily balance your setup, then lock the R.A. and Dec. axes so that they cannot move when the motors are engaged.

Image past the meridian:

The 1100GTO mount will track and guide well past the meridian in either direction if the object is located such that the telescope will clear the pier. This allows the user to set up the mount for a long series of exposures without stopping in the middle to flip sides. One can start the telescope under the mount while pointing at an object in the eastern part of the sky and track it all the way deep into the western sky. This is very useful for long exposure H-alpha or in cases where a large number of individual exposures are needed for stacking. This feature of AP GTO mounts has been a real customer favorite:

"The 1200GTO's ability to continue tracking when past the meridian is an absolute winner for me. It avoids meridian flips (=imaging time) and reduces the need for expensive rotators." - Jan Rek

". . . I love the ability to place the OTA on the "wrong side" of the mount when starting an imaging session ("premature meridian flip") and which I have used extensively. This feature is pure INGENUITY!" - Anthony Ayiomamitis.

Easy alignment for critical viewing.

You can align the 1100GTO using setup routines in the optional keypad for most non-critical observing. Our optional Right-Angle Polar Alignment Scope will allow you to quickly zero in on the pole or the polar alignment routine in PEMPro (included) will guide you through the process. You can even align the mount during the day with our clever Daytime Polar Alignment Routine (outlined in the Keypad Manual) for solar observing, viewing the planets at twilight, or just getting a jump start on a long night.

Multiple Options for Controlling your Mount in the Field or Your Observatory:

You have your choice of the GTO Keypad (optional), which is a full-featured handheld computer, PC computers using a wide variety of software with or without our ASCOM driver, Mac computers or even your mobile smart device (like your iPhone or iPad).

AP 1100GTO Mechanical Features

Precise Mechanical Fabrication

Using modern CNC machining techniques, we make all components to a high precision level, which results in a final package that is solid and accurate in all respects. The critical angles are accurately machined so that the mount is orthogonal to a very high degree. This results in pointing accuracies well below 1 arc minute for a properly aligned mount. Massive thrust bearings and preloaded shaft bearings provide excellent stability under all imaging situations.

Easy to Adjust and Maintain

The design of the 1100GTO is straightforward with modular construction. We provide information in the Technical Support section of our website pertaining to typical adjustment issues.

Components are modular.

All electronics including the GTOCP4 control box, motors, gearbox or cables can be removed for servicing. The RA and Dec axes can be shipped separately, if needed.

GTOCP4 Drive System

Like the previous GTO mounts, the GTOCP4 drive system uses a high-quality Swiss DC servo motor controlled by a microprocessor to an accuracy of 0.05 arc-seconds per step. Tracking is very smooth, noticeably smoother than any stepper motor drive or inexpensive servo motor. The system can be accurately controlled over a speed range of 4800:1, which allows 0.25x sidereal for manual guiding to 1200x sidereal for 5 degree per second slewing. The circuit draws approximately 0.5 amps when tracking the stars, 2.5 amps with both motors slewing and requires only 12 volts to operate. The servo drive will satisfy the requirements of the sophisticated, advanced astro-imager, yet is easy for the casual, visual observer to use.

Gear Accuracy and PE Performance

The heart of this mount is a precision gearbox using custom high-quality fine-pitch gears, coupled to a highly accurate worm and worm wheel. These parts are manufactured and assembled at our facility and individually tested to meet or exceed our periodic error specification of 7 arc seconds (+/- 3.5 arc sec.) before introducing any periodic error correction. The PE is smoothly variant with extremely low ripple or moment to moment error. In contrast, mounts that use commercial gearboxes have very small spur gears with tiny teeth and too few of them. This generally causes ripples in the tracking rate which are difficult to guide out.

Each mount is rigorously tested on our specialized periodic error tester. Only mounts that provide an accuracy of 7 arc seconds or better will pass this inspection. If the mount exhibits greater error, the substandard part is identified, replaced and the mount is retested.

Pre-loaded PEMPro Curve

As mentioned above, the spec of 7 arc seconds (+/- 3.5 arc sec.) is the maximum native mechanical error inherent in the mount's RA axis WITHOUT any software correction. In order to optimize performance even further, we use a special version of Ray Gralak's PEMPro developed specifically for our test equipment. We generate a unique PE curve for each mount that we program into each GTOCP4 Control Box. Simply use the optional Keypad or your Astro-Physics software (ASCOM V2 driver, PulseGuide or APCC) to turn the PE Correction "on" and you will see results significantly better than our published 7 arc second spec without additional PEMPro runs! However, you may use PEMPro to further refine your PE, if you chose to do so.

1100GTO-AE or 1100GTO-AEL: If you purchase either of these versions with absolute encoders, the final in-house PEMPro run will utilize the corrections of the absolute encoders and the values will be stored in the GTOCP4 Control Box.

GTOCP4 Control Box

The GTOCP4 Control Box contains all of the circuitry to drive the two servo motors and the logic required to navigate the sky. It can be easily removed from the mount, if required. The 1100GTO uses the same GTOCP4 Control Box as the 1600GTO and Mach1GTO (the control box is black-anodized for the latter mount). In fact, the control boxes for all three mounts are interchangeable with one another in an emergency. However, the absolute encoder function is only available in the control boxes sold with those mounts.

GTO Keypad (optional purchase)

The Keypad is a self-contained computer that allows you to control all essential telescope functions and includes an extensive database of objects. We have designed the interface and firmware to be as intuitive and easy to use as possible, while filling it with terrific features to make your observing session productive and pleasurable.

Pier Mounting Options:

The 1100GTO mount integrates a precision rotating pier adapter and azimuth adjuster as part of its base. The mount's base will directly attach to the Astro-Physics pier, or it can be attached to any flat surface using the Flat Surface Adapter for 1100GTO and all 900 Mounts (119FSA). If you plan to use an 8" ATS pier, you will need the Flat Surface Adapter with Flat Pier Plate for 1100GTO and all 900 Mounts (119FSA-FP). The 1100GTO's wide adjustable 0 to 78 degree latitude range (which spans from Antarctica to the arctic circle) makes the use of a wedge unnecesary.

Items that You will Need for Your Mount

Mechanical Specifications

| Construction |

All CNC machined aluminum bar stock, stainless steel, brass; stainless steel fasteners |

| Finishing and Assembly |

Every part is hand-finished and inspected. All assembly is done by hand, by highly skilled mount assembly staff. |

| Worm wheel - R.A. & Dec. |

7.2" (183 mm), 225 tooth aluminum |

| Worm gear - R.A. & Dec. |

0.71" (18 mm) diameter special low-wear alloy |

| Axis shaft - R.A. & Dec. |

3.15" (80 mm) diameter |

| Shaft axis bearings - R.A. & Dec. |

3.94" (100 mm) diameter |

| Latitude range |

0 to 78 degrees |

| Azimuth adjustment |

Approximately 18 degrees (+/- 9 degrees from center) |

| Counterweight shaft |

1.875" (47.6 mm) diameter x 14" (356 mm) long [12.875" (327 mm) usable length], incl. large machined safety stop knob. Optional 9" (229 mm) shaft extension available. |

| Weight of mount |

Total: 54.0 lb. (24.5 kg)

R.A. axis/polar fork: 26.0 lb. (11.8 kg)

Dec. axis: 16.0 lb. (7.3 kg)

Dec. top plate 1.5 lb. (0.7 kg)

Counterweight shaft: 10.5 lb. (4.8 kg)

|

| Capacity |

Approximately 110 lb. (50 kg) scope and accessories (not including counterweights), depending on length. Recommended for refractors up to 200 mm, 14-16" Cassegrains, Ritchey-Chretiens and CDKs.

These are only guidelines. Some telescopes are very long for their weight or heavy for their size and will require a larger mount. Remember also that imaging requirements are more rigid than visual observation. Maximum capacity may require the use of the 9" extension (M12675) |

| Instrument mounting interface |

Refer to list of suitable mounting plates |

| Pier adapter base diameter |

7.730" (196.3 mm) Base. The base is an integral part of the mount and azimuth adjuster.

|

GTOCP4 Servo Drive System Specifications

| Electronic components |

Rated for industrial and automotive applications |

| Motors |

Zero-cogging Swiss DC servo motors, enclosed in machined aluminum housing |

| Motor encoder |

2000 tic quadrature yielding an effective resolution of 0.050 arcseconds per tic |

| Motor reduction gear train |

57.6:1 gear reduction through a custom built set of large diameter, fine-toothed, precision, spur gears for vastly superior performance |

| Servo Motor Control Box |

GTOCP4 Control Box, removable |

| Hand-held computer (optional) |

GTO Keypad to control all mount functions. Includes extensive databases and tour features in a simple, intuitive interface. Firmware updates via the internet |

| Power consumption |

~ 0.3 to 0.6 amps at 13.8 volts - tracking

~ 1.3 to 2.5 amps at 13.8 volts - both motors slewing at 1200x |

| Power requirements |

Nominal 12 volt DC supply at minimum of 5 amps continuous |

| Periodic error |

7 arc seconds peak-to-peak (+/- 3.5 arc seconds) or less in one worm cycle (6.4 minutes); native, prior to any error correction

|

| Maximum slew speed |

5 degrees / second |